*Ongoing Implementation

Companies are targeted for tracking, audit and inspection of product’s regulatory rule adherence. Failure to do so results in penalties and operational disruption with a huge business impact. With an in-place Product Compliance Engine a timely and effective response is possible. The engine would provide a comprehensive audit trail even to the last level supplier in the chain.

Ability to identify substances and materials of concern and list all the impacted products at a design stage itself is very important. The engine would provide visibility to the component, supplier and alternatives to quickly course correct much ahead of future expensive product lifecycle stages.

In the B2B chain, inability to respond to customers requests could mean lower customer retention. The quality and timeliness of the response is critical for customer satisfaction.

Dodd-Frank Wall Street Reform and Consumer Protection Act (Conflict Minerals Law) and California’s Supply Chain Transparency Act mandates a transparent supply chain. It allows to assess impact on suppliers when a new restricted substance is introduced.

Working through the supply chain to establish and manage compliance is a laborious and frustrating exercise. The Product Compliance Engine automates most of this task with adherence to industry standard exchanges like IPC. Re-assessing your BoM with a changed regulation and perform What-If analysis can save weeks of effort for the components engineer.

Apart from the internal cost of deploying component engineers and involving 3rd party experts for analysis and audit trail dissemination, cost of business interruptions and penalties of non-compliance can be overwhelming.

An accentuated environmental credential presents a positive perception helping to surge ahead of competition.

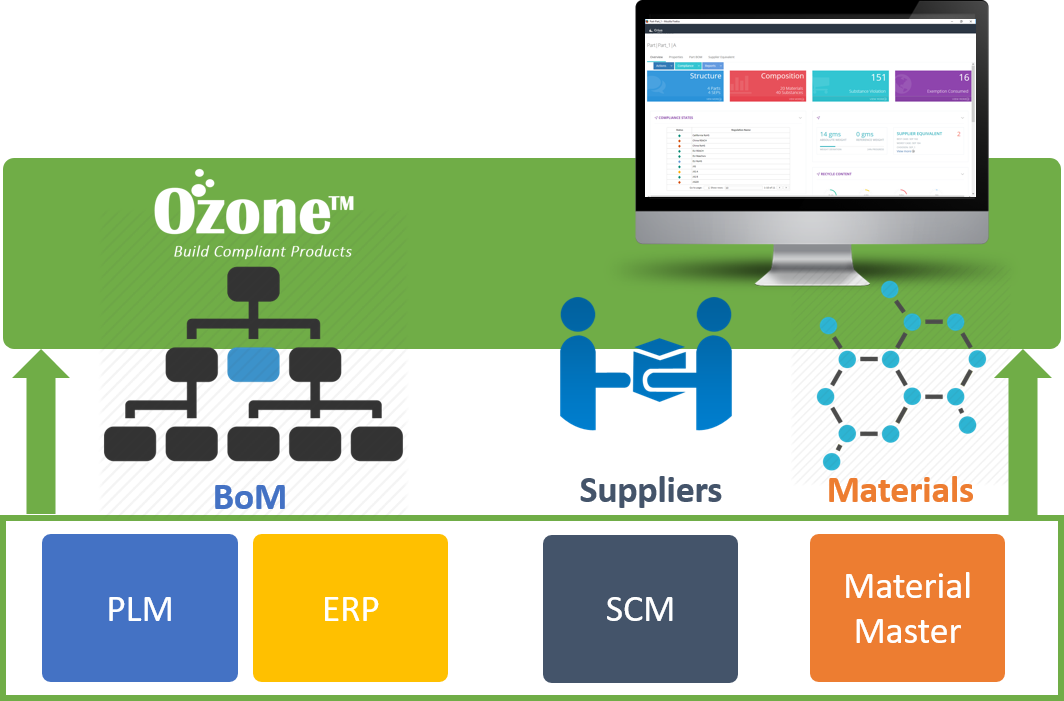

Product Structures and BoM with embedded materials and substance structure for a comprehensive view of the product composition. This is validated against active regulations providing a detailed audit trail of the compliance index at all levels of the product structure. Explore weights, costs, alternatives, substances of concern (SOC), country of origin, conflict minerals, reuse and recyclability with Ozone.

Integrated dashboard for external supplier and customer access. Suppliers and the host company can interface with the latest IPC (175xx) & IMDS exchange standards validated live with latest regulation rules and material/substance composition – all under a embedded security levels for IP protection. Component Engineers can accept, verify, approve and reject supplier declarations in an interactive dashboard.

Ozone provides advanced analytics at various levels for different end user roles – Administrator / Engineer Management Dashboards with advanced drill-down and self-help capabilities.

Regulation comparison, What-If Analysis, Compliance Index Card, Conflict Minerals audit report, REACH Analysis, Recycle Reports, Substance impact & Where-Used, Location intelligence, Supplier Scorecards and many other analysis/reports helps engineers to assess, analyze and report compliance with great ease. It helps your organization establish proactive and corrective measures on ever increasing regulations and their mandates.

The US Dodd Frank Act mandates companies to identify and disclose to the US Securities and Exchange Commission (SEC) any sources of 3TG used in their products if they originate in or around the Democratic Republic of the Congo (DRC). The 3TG list assessed:

01. Cassiterite (ore for tin): tin is used as solder on circuit boards in every electronic device we use. 02. Columbite-tantalite (coltan, ore for tantalum): tantalum stores electricity and is essential to portable electronics and high-speed processing devices, such as laptops and cell phones. 03. Wolframite (tungsten, wolfram, ore for cobalt): commonly used in tools; enables cell phone vibration. 04. Gold: used in the wiring of electronic devices Or their derivatives and any other mineral, or its derivatives, as determined by the Secretary of State to be financing conflict in the Democratic Republic of the Congo or an adjoining country.

Ozone helps in the following areas of the conflict minerals reporting process:

01. Discover the presence of 3TG in the product structure and supply chain. 02. Inquiry, collection and verification of Smelters for Reasonable country of origin inquiries (RCOI). 03. Conduct due diligence and audit trail for evidence, Establish and regulate the source of 3TGs from the DRC. 04. Analyze, report and certify conflict minerals status of the product structure and supply chain.

Ozone battery module validates the manufacturing and disposal of batteries or accumulators against the Directive 2013/56/EU (amending 2006/66/EC) deals with battery classifications, labeling and validates the following substance prohibitions:

More than 0.0005% (5ppm) of mercury (Hg) by weight.

More than 0.002% (20ppm) of cadmium (Cd) by weight.

With respect to EU Packaging Directive Directive (EU) 2015/720 (amending Directive 94/62/EC), Ozone Packaging Regulation module validates the presence of heavy metals Mercury (Hg), lead (Pb), cadmium (Cd), and hexavalent chromium (Cr6) beyond permissible limits. It also provides the recycled reference indices, volume and weight of packaged materials used against the targets. With the April 2015 directive, the usage of lightweight plastic bags is also governed.

Ozone is an end-to-end hosting system in managing your complete compliance needs from product structures, materials, substances, supplier information and much more. Alternatively it also provides a compliance wrapper that can integrate seamlessly with your source systems that contains information needed for computing product compliance values. It is facilitated with data management modules for BoM, Materials, Substances, Supplier and many other compliance datasets that help integration, extraction and dissemination of compliance information to external systems. So, connect your enterprise applications with Ozone to determine compliance of your products or embed Ozone in your native applications, choice is yours!

Component Engineers can export product compliance information in various formats – IPC-175x, IMDS, HTML, Excel, JSON and others to report compliance to customers.

Ozone provides a compatible interface to BOMCheck.net to download/upload supplier submissions based on product or supplier identities.

Ozone compliance engine is available as an on-premise or cloud application based on your preference.

On-Demand compliance with Ozone Lite:

If you are an organization that doesn’t have a Product/BoM management system, feel free to use Ozone Lite that has flexible modules to provide a compliance assessment for your product structures

Organizations with large product structures can track, analyze and report for compliance with the incredibly fast Ozone compliance core. Talk to us for more statistics.

Integrated material-aware product design for producing environmentally compliant products.

Auditable compliance system for regulatory bodies and customers avoiding huge penalties and operational disruption with a huge business impact.

Automated standards-based interchange with suppliers/customers reducing errors and rework.

Quickly assess impact on products and suppliers when a regulation changes and new restricted substances are declared.

Analytics for smarter decisions about compliance can save a lot of time and money.

Embeddable compliance wrapper for your systems (PLM, CAD, ERP, SCM or home-grown) and processes leveraging existing investments.

Protecting brand value and reputation with an accentuated environmental credential increasing customer satisfaction and surging ahead of competition.