Building Digital Solutions that Factories Desire!

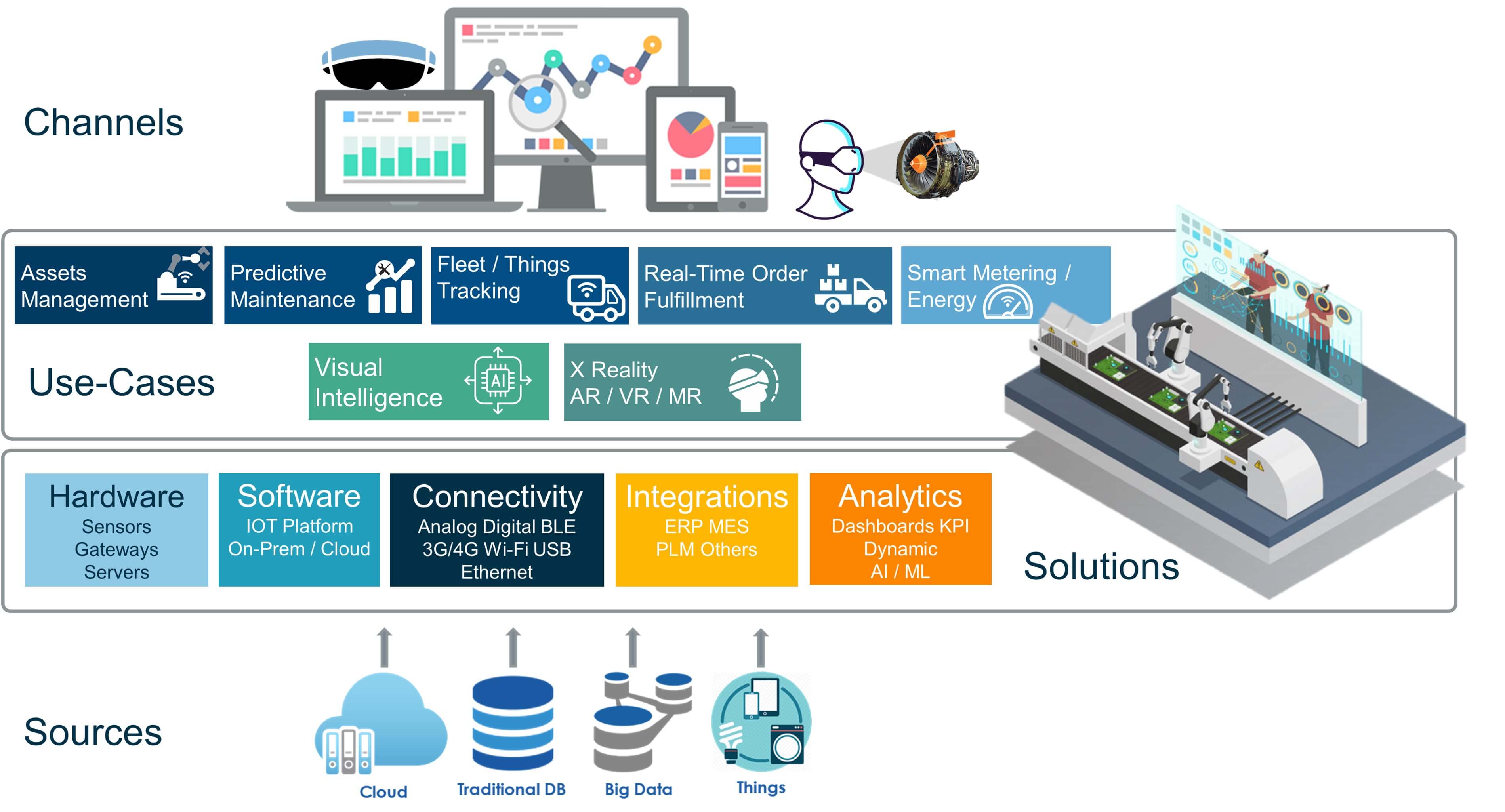

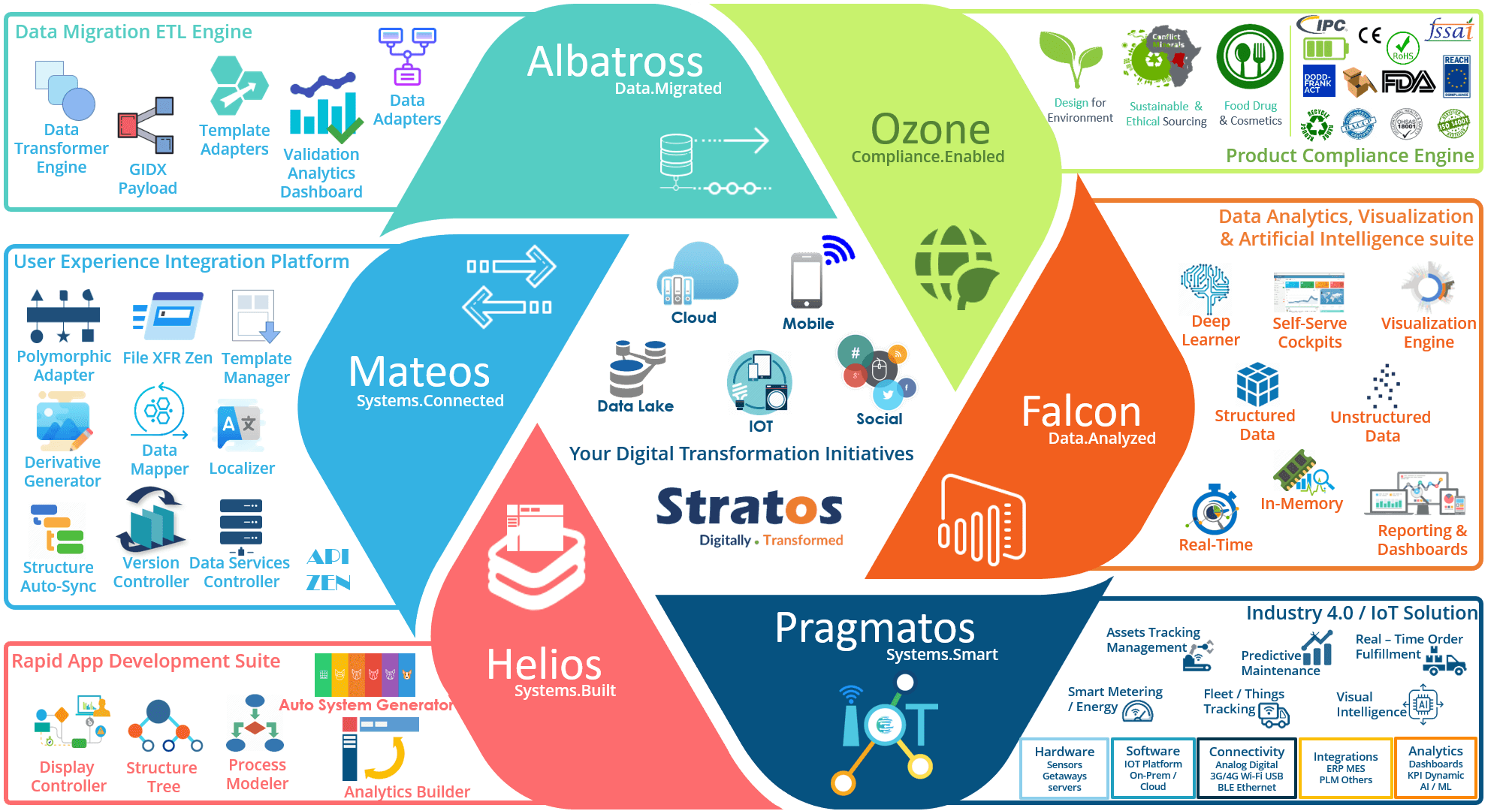

As a Cognitive Internet of Things (IoT) solutions company, we provide Industrial IoT and Artificial Intelligence based Automation. Our Solutions are designed to simplify the technology challenges in adopting the Industrial Revolution from Strategy through implementation and support.

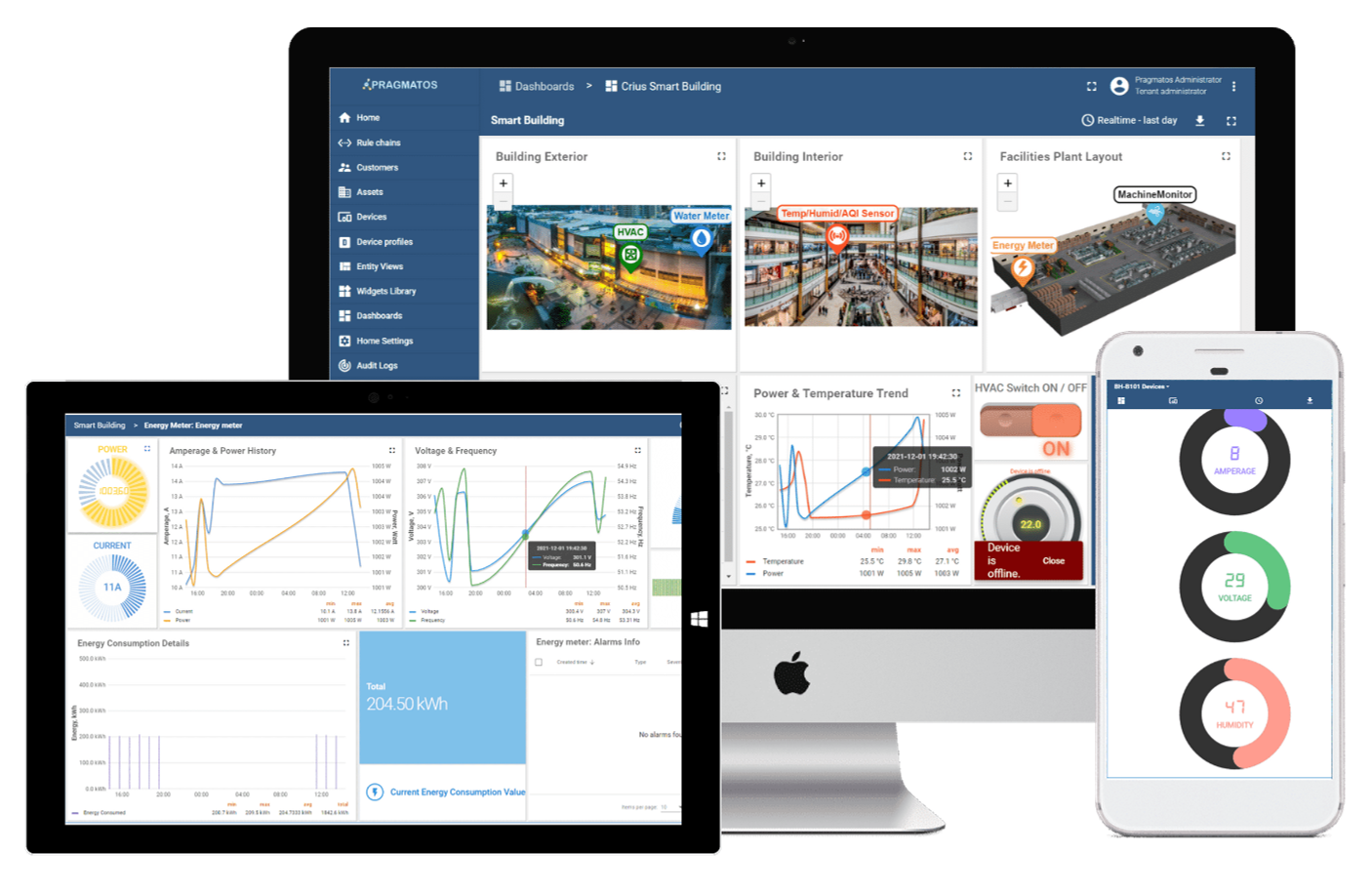

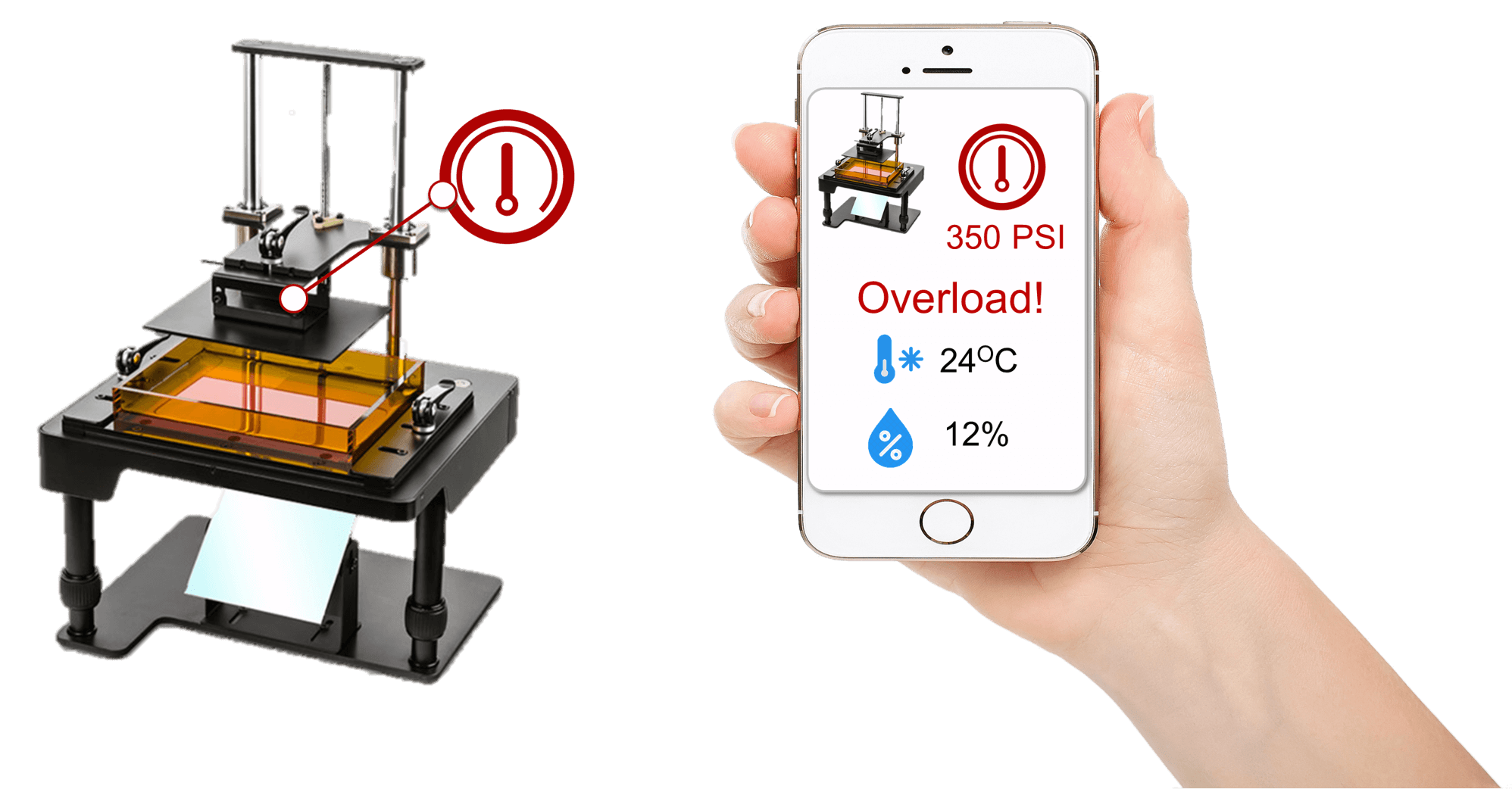

Provides everything you need to build your Industrial IoT infrastructure and Assets / Device Management. This Low-Code IoT Platform has a wide range of features from Device Agnostic, IoT Network ( WiFi, Cellular, LoRaWAN, Sigfox, NB-IoT and more ), On-Premise / Cloud Storage, Rules Engine, Alerts, OTA, Commands, Data Analytics, and Visualization.

Prevent issues or potential failures of your assets before they happen

Predictive maintenance with IOT can reduce asset downtime by 40%.

Predictive maintenance can lower op-ex by up to 30%.

Boost Asset usage by about 35%.

Monitor important assets 24/7.

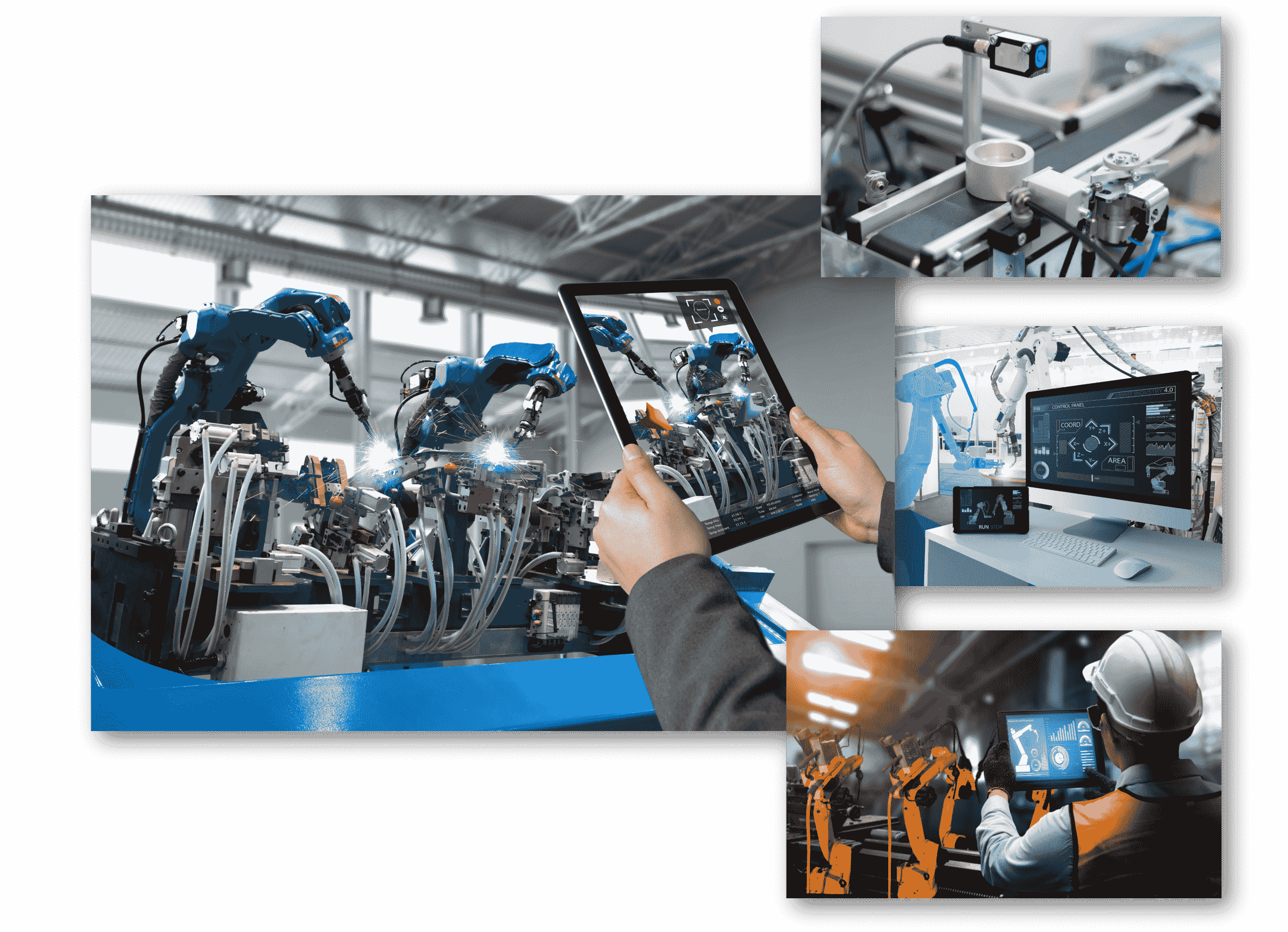

With our Artificial Intelligence driven predictive maintenance solutions, you can monitor the condition of industrial equipment, forecast potential failures and schedule service maintenance. limits inefficiencies, improves safety, and saves you money. See the video for Smart Digital Factory in action -

Real-time monitoring of assets & factory conditions.

Monitor critical assets, locate toolkits & optimize performance

Capture telemetry with proximity, pressure, temperature, humidity and vibration sensor data.

Real-time asset tracking with in-factory assets / tools tracking or geolocation mapping services.

Remote control asset behaviors with advanced configuration from anywhere

Extend & upgrade assets with remote firmware

Historical performance tracking: Track asset performance history to extend optimal usage or increase accuracy of quality prediction.

Track vehicles in real-time & control them remotely

Monitor your Fleet at scale in Real-Time:

Real-time Geo-location Tracking with preferred accuracy

Historical location tracking: Track Fleet history to suggest optimal routes or increase accuracy of information needed for business intelligence.

Capture telemetry with pressure, temperature, humidity, fuel, mileage and vibration sensor data.

Visual Intelligence with fleet inners and surroundings, prevent misuse.

Control fleet-wide asset behaviors with advanced configuration.

Extend capabilities with over-the-air firmware updates.

Smart fleet solutions can reduce fuel consumption by 17%

Fleet management can help companies decrease repair costs by up to 25%.

Reduce administrative costs by 10%.

Real-time monitoring and automated order

IoT-driven order fulfillment can help better organize inventory and reduce costs by 15%

Real-Time order fulfillment can help reduce missed sales opportunities by 20%

Orgs that use IoT-driven fulfillment see a 20% increase in customer satisfaction

Real-time monitoring of storage levels with notifications and alerts

Replenish supplies with automatic order processing

Integrate with ERP & Order Management solutions.

Real-time monitoring of Orders through the supply chain

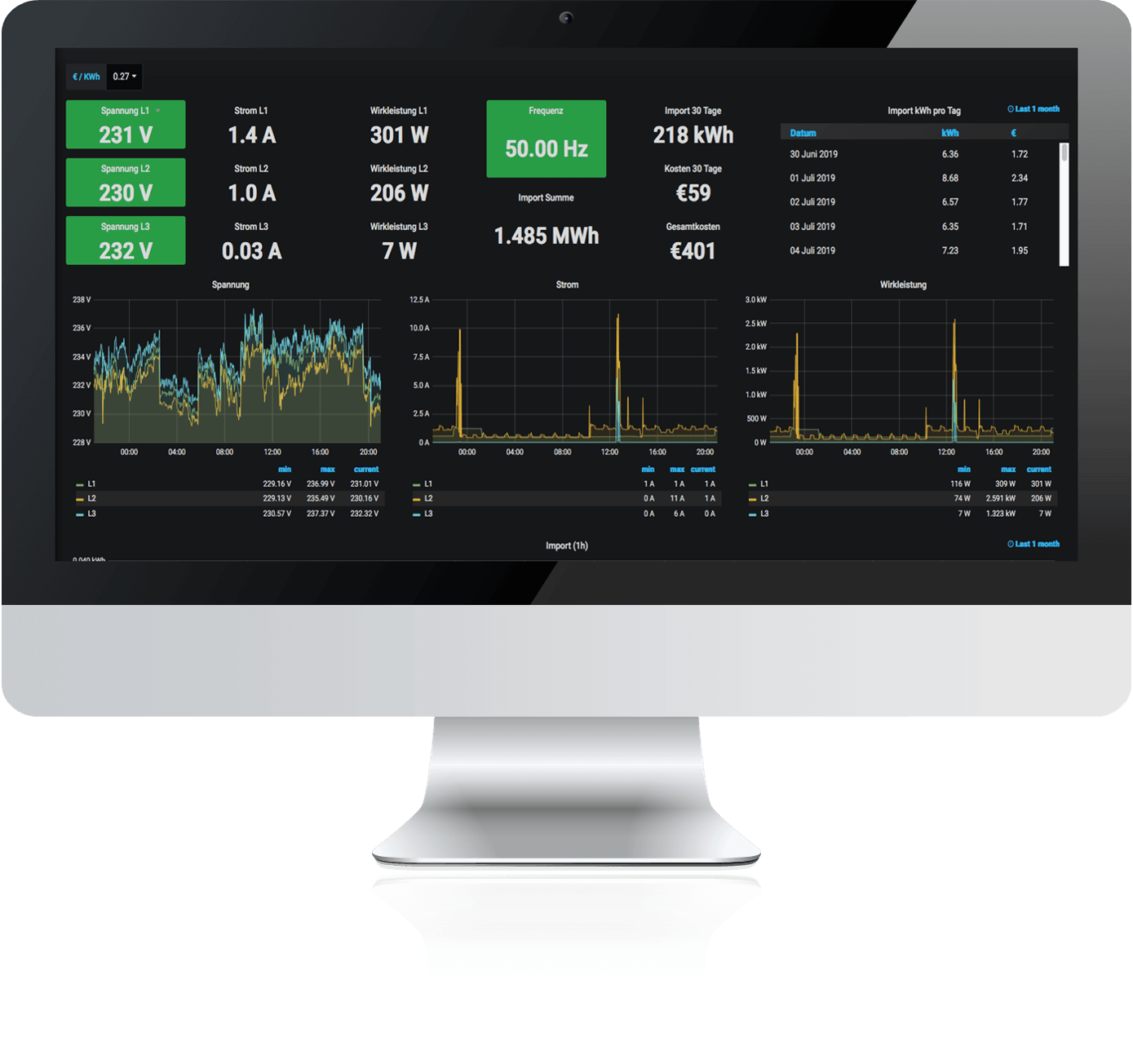

Real-time monitoring and measurement of water, power or natural gas

Gain the ability to remotely control your assets, fleet and/or devices

RS485 half/full duplex mode

Low power wireless (Sub 1 GHz) radio

128 simultaneous wireless nodes

Material: ABS, PLA

Dimensions: 103 mm x 116 mm x 33 mm.

32 bit micro controller with firmware

3 Analog, 8 Digital & 3 Relays

GPRS, Wi-Fi, 4G/LTE, LoRa & NB IoT

Supports MQTT, UDP, HTTP, CoAP, SPI, I2C, 1-Wire, RS485 / MODBUS and RS232

IP 20 / 67 /68, Material - ABS.

Two Way communication

10~30V DC wide power range input

Radio Signal Coverage up to 6KM

Low Power Wireless Access

20 set constant register

-40 ~ 75°C / 90%H Operating Temperature / Humidity.

Wi-Fi 802.11 b/g/n

Channel Frequency: 865-867 MHz

Tx Power: +13 dBm

Sensor Range: -50 0C to +125 0C

Channel Frequency: 865-867 MHz

Tx Power: +13 dBm

Sensor Range: -25 0C to +60 0C

0% RH to 100% RH

Channel Frequency: 865-867 MHz

Tx Power: +13 dBm

Battery: CR2032 x 2

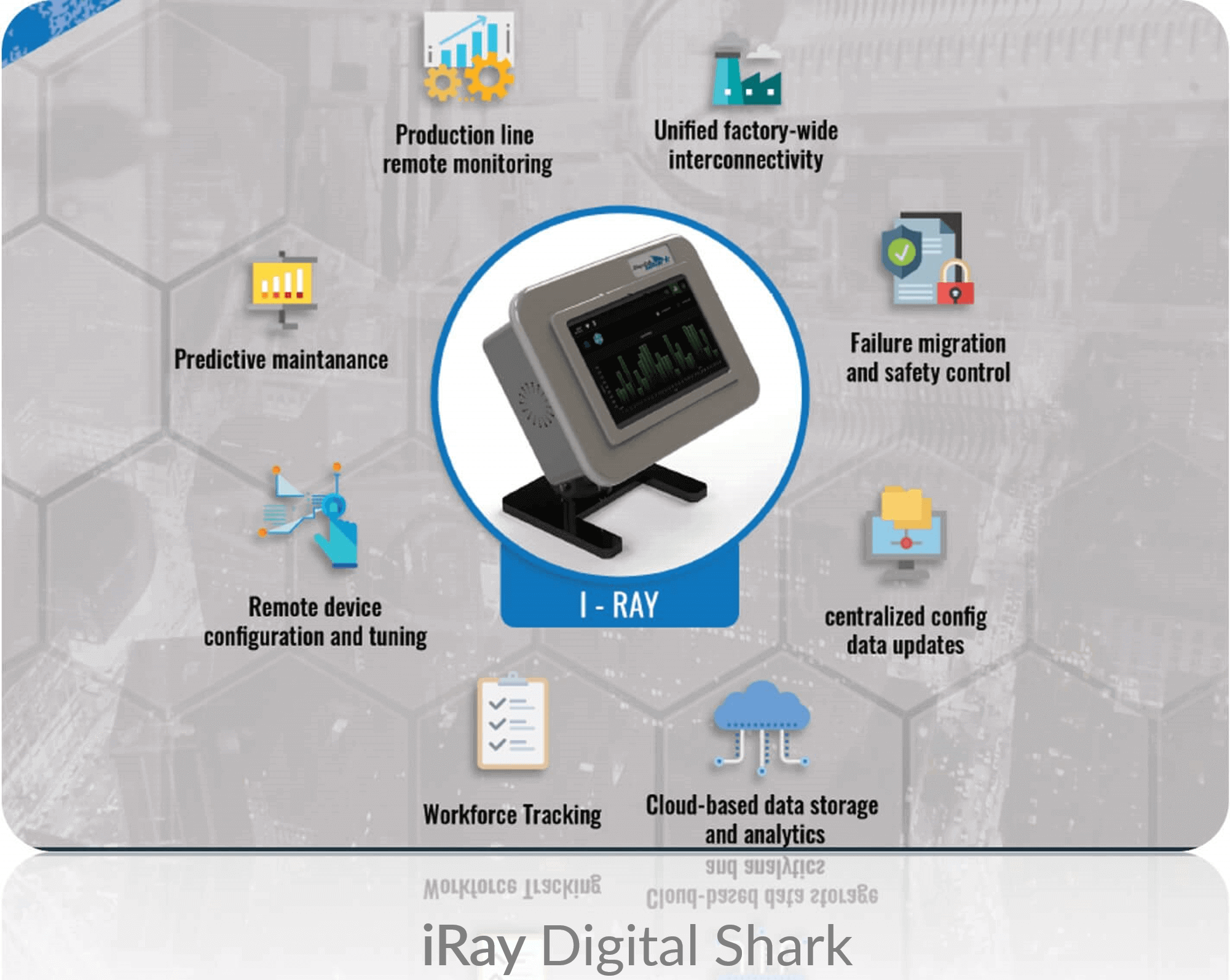

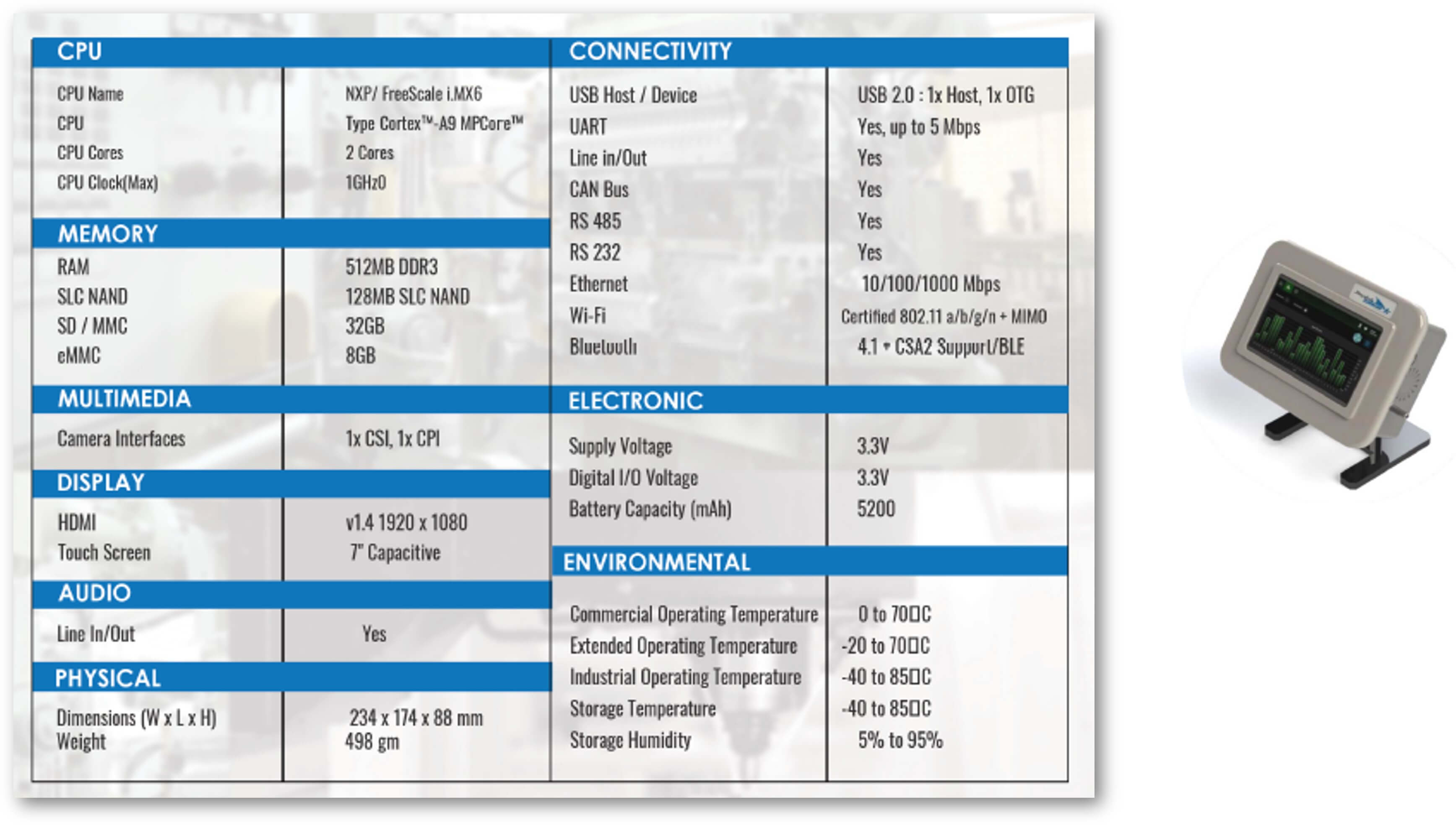

Connect to CNC, PLC, Sensors and Other Machines.

ModBus, ProfiBus, DNP3, RS232, Fanuc, Siemens and custom.

OPC, CANBus, Analog/Digital inputs, BLE4.0, Wif-Fi, USB, Ethernet.

Modberry M500 Advantech controllers Wireless or Connected Sensors.

Devices / assets, their data, protocols and rules managed in a simple way

Hardware agnostic – Microcontroller Plug-N-Play – iRAY, Arduino, Intel Edison, Raspberry PI, Particle, arm MBED and more

Asset Management – Register, Manage, Control Devices remotely.

Collect Reliable device data that survives Network and Hardware failures

MQTT, CoAP, HTTP ModBus, ProfiBus, DNP3, RS232, Fanuc, Siemens and other standard/custom protocols. Bluetooth (BLE4.0), WiFi, LoRaWAN, RFID, OPC, CANBus, Analog/Digital inputs, USB, Ethernet.

Control Incoming Device Data with custom Rules and complex application logic with a Drag-N-Drop UI Designer.

Real-Time Data Visualization.

Drag-Drop, Plot & Aggregate

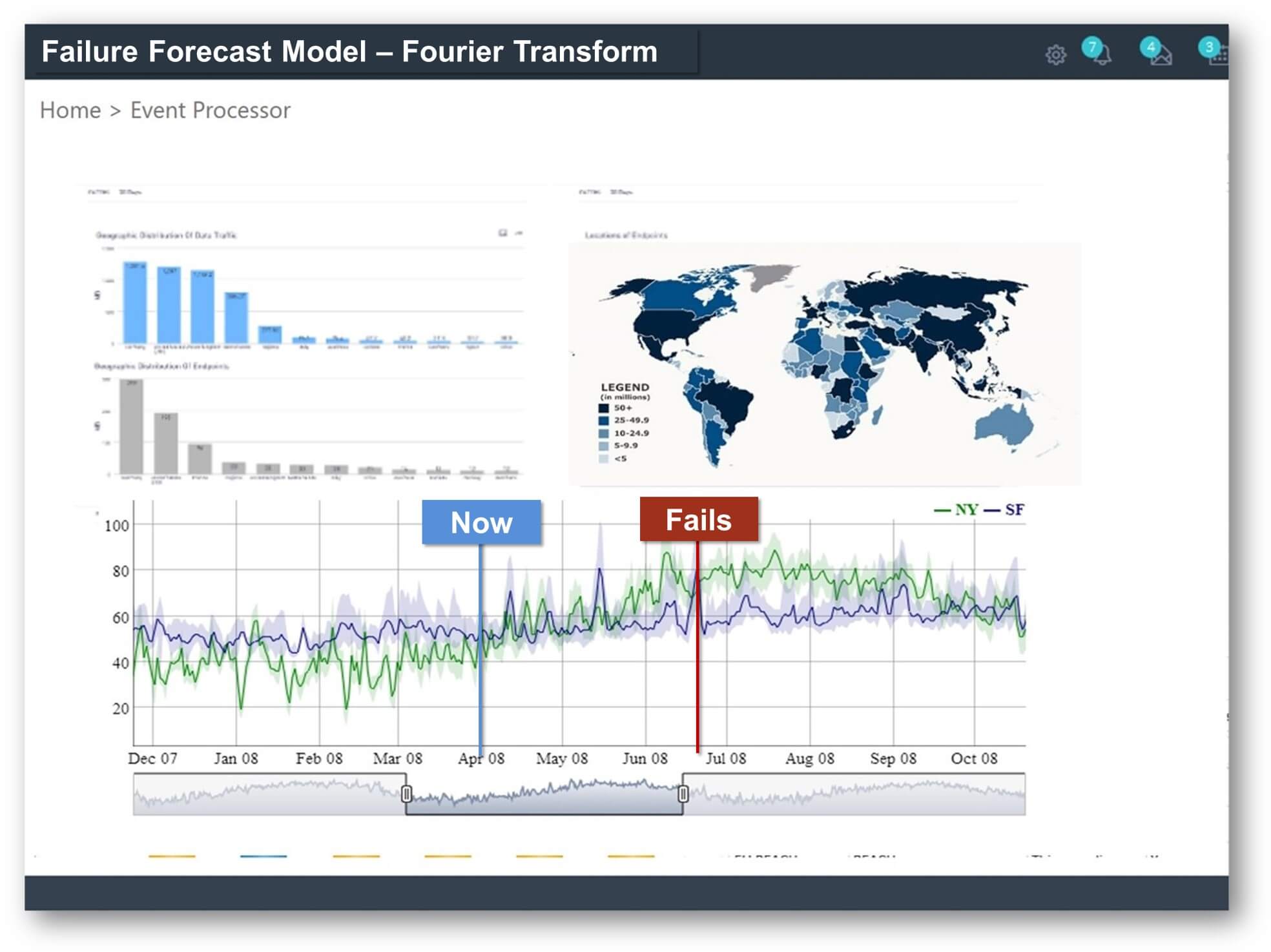

Predict Failures & Forecast Utilization.

Monitor equipment utilization to assess the performance, productivity and time based trends of lower and higher usage.

Predict & Set the limit run time threshold as rules to trigger automated maintenance orders.

Explore the data generated by machinery to understand the high performance periods and predict failure.

Measure IoT Data to analyze the overall productivity across all assets to arrive Overall Equipment Effectiveness (OEE).

Solution implementation plan, methodology, plan & key phases